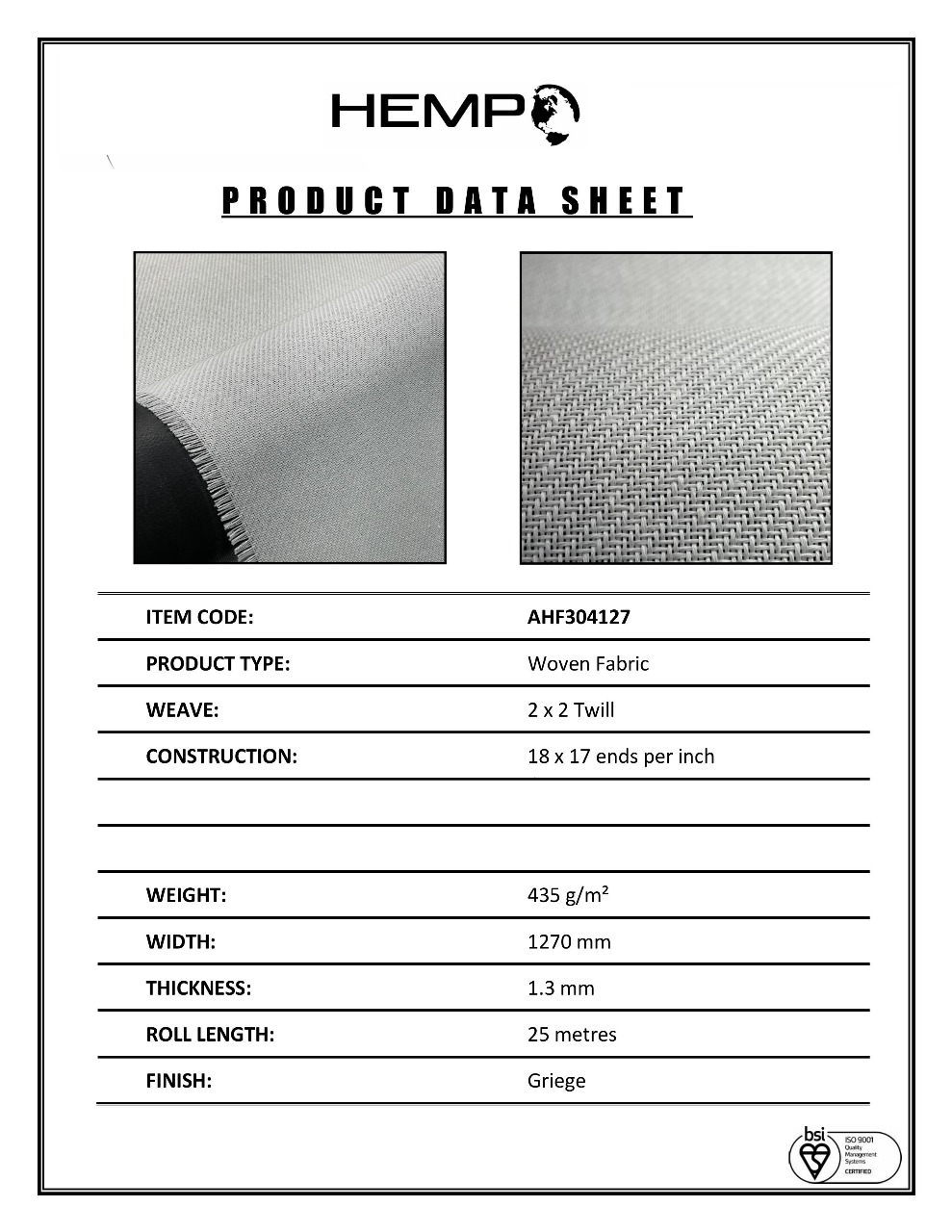

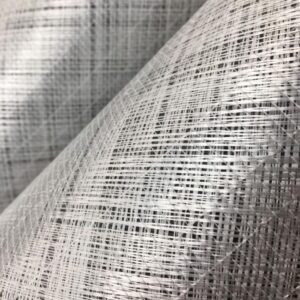

HEMPEARTH AHF304127 – Hemp Woven Fabric Twill 435g/m2 x 1270mm – 25 Meter Roll $55 Per Meter

Product description

Innovation that works: The combination of leading edge technical HEMP fibers with collaborative, process-driven solutions

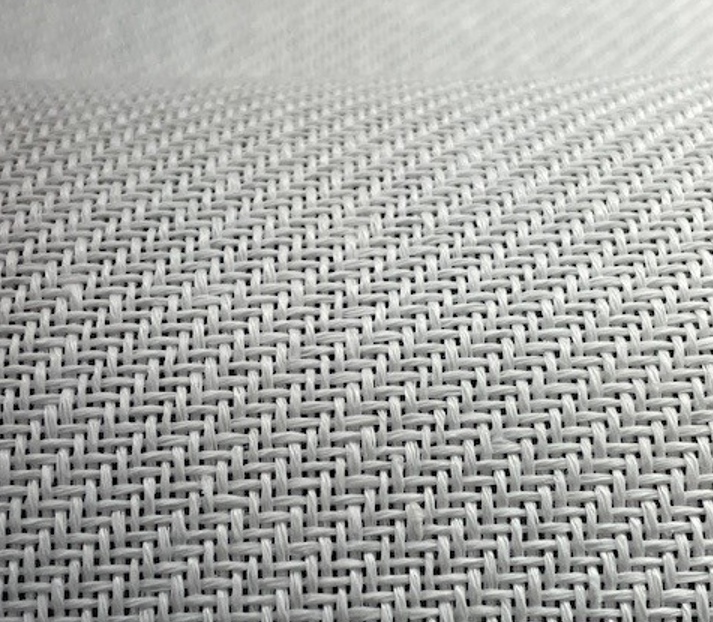

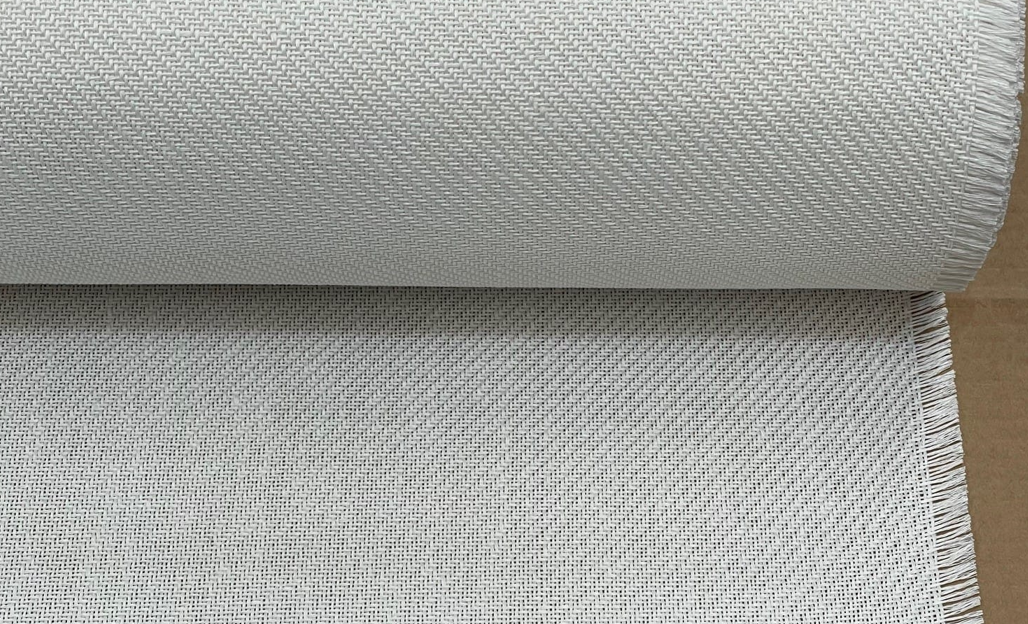

HEMPEARTH™ 2×2 twill is an environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass and carbon fiber. As well as its environmental credentials, hemp fiber/polymer has an attractive natural aesthetic and excellent vibration damping properties. Suitable for all laminating processes, including hand-layup, vacuum bagging and resin infusion.

Further advantages are vibration damping properties which are much greater compared to glass or carbon fiber, and less fragile fracture behavior than carbon fiber.

Key performance advantages:

- Very high specific stiffness and strength

- Architecture optimized for composite processing and performance

- Reliable and highly consistent performance across batches

- Viscoelastic behavior providing very efficient vibration damping

- Excellent inherent compatibility with thermosets via covalent bonding

- Very low CTE, hence high thermoelastic compatibility with carbon fibers

- Highly radio-transparent across the entire RF spectrum (1 – 40 GHz) even in thick laminates

- Long fatigue life cyclic loading

- Compatible with vacuum infusion, wet lay up RTM, BIM, autoclave processes and compression molding

This 435gsm hemp cloth is the 2nd lightest of our woven hemp cloths. Its fine weave and smooth texture is well suited to use as a surface ply.

About Hemp fiber/polymer

Hemp fiber/polymer is environmentally friendly, non toxic, and a sustainable alternative to traditional composite reinforcements such as glass or carbon fiber.

How to Process

Hemp fiber can be processed in a similar way to most dry composite reinforcements including glass or carbon fiber reinforcement and is suitable for use with a wide variety of resins such as epoxy, vinyl ester and polyester resin, including more sustainable or environmentally friendly synthetic and bio-based systems. Hemp reinforcement can be used on its own or in conjunction with other types of reinforcement, including glass or carbon, to achieve the desired properties or appearance.

Dry hemp fiber can be laminated using a range processes including hand layup, vacuum bagged hand layup, resin transfer molding (RTM) and resin infusion.

It is particularly well suited to resin infusion with the fiber’s structure allowing good resin flow through the laminate. The vacuum consolidation results in a high fiber to resin ratio and the vacuum infusion process produces void free laminates with an excellent visual appearance.

Uses

Twill Weave

Aviation: All Small molded parts in aircraft, the weave allows stretching or collapse regardless of how the mold is designed.

Marine: boat hulls, decking and cabin panels.

Automotive: racing seats, interior panels and non-structural outer panels.

Recreational: kayaks, canoes, stand-up paddle boards, dinghies, yachts

Industrial: liquid storage tanks, interior wall / ceiling panels, exterior building facades, furniture, architectural molding’s, and panels, parcel shelves and door liners.

How to Buy

This 435g hemp fiber/polymer cloth is 1.27m (39.37″) wide and the fabric is sold by the linear meter on 25 meter rolls. Simply enter the qty according to the number of linear meters you want to buy; the fabric will be supplied in 25 meter rolls.

Please note: Our hemp/polymer composites come on a 25 linear meter rolls

Minimum Order Sample 25 meters

Storage

Hemp fiber/polymer should be stored in a cool dry place away from direct sunlight. Hemp fiber/polymer can absorb moisture from the atmosphere so drying may be required before use, especially if exposed to excessive humidity.

$55 Per Meter

All composite materials are shipped Via DHL.