(HEMPEARTH)

Composite materials are widely used in the Aircraft Industry and have allowed engineers to overcome obstacles that have been met when using the materials individually. The constituent materials retain their identities in the composites and do not dissolve or otherwise merge completely into each other. Together, the materials create a ‘hybrid’ material that has improved structural properties.

The development of light-weight, high-temperature resistant eco, sustainable composite materials will allow the next generation of high-performance, economical aircraft designs to materialize. Usage of such materials will reduce fuel consumption, improve efficiency and reduce direct operating costs of aircraft.

Composite materials can be formed into various shapes and, if desired, the fibres can be wound tightly to increase strength. A useful feature of composites is that they can be layered, with the fibres in each layer running in a different direction. This allows an engineer to design structures with unique properties. For example, a structure can be designed so that it will bend in one direction, but not another.

Composites have good tensile strength and resistance to compression, making them suitable for use in aircraft part manufacture. The tensile strength of the material comes from its fibrous nature. When a tensile force is applied, the fibres within the composite line up with the direction of the applied force, giving its tensile strength. The good resistance to compression can be attributed to the adhesive and stiffness properties of the base matrix system. It is the role of the resin to maintain the fibres as straight columns and to prevent them from buckling.

Environmental impact

There is a shift developing more prominently towards Green Engineering. Our environment is given increased thought and attention by today’s society. This is true for composite material manufacturing as well.

As mentioned previously, HEMP composites have a lighter weight and similar strength values as heavier materials. When the lighter composite is transported, or is used in a transport application, there is a lower environmental load compared to the heavier alternatives. HEMP Composites are also more corrosion-resistant than metallic based materials, which means that parts will last longer. These factors combine to make composites good alternate materials from an environmental perspective.

Conventionally produced composite materials are made from petroleum based fibres and resins, and are non-biodegradable by nature. This presents a significant problem as most composites end up in a landfill once the life cycle of a composite comes to an end. There is significant research being conducted in biodegradable composites which are made from natural fibres. The discovery of biodegradable composite materials that can be easily manufactured on a large-scale and have properties similar to conventional composites will revolutionize several industries, including the aviation industry.

Why Build A Plane Made From Hemp?

HEMP/Cannabis, in addition to being one of the world’s healthiest, and most versatile plants on earth, HEMP is pound for pound 10 times stronger than steel. This means that it can withstand a lot more weight before and breaks, and it can bend way further than metal. Great for Aviation. Hemp is significantly lighter and therefore requires a lot less fuel to get up in the sky.

Most importantly, hemp is an environmentally friendly material. Hemp requires way less water and land to grow than cotton and even puts nutrients back into the soil through a process called phytoremeditation.

Compared to steel, which requires mining, or carbon fiber, produced from plastic, hemp has almost no environmental impact.

Who Designed It

Canadian cannabis company Hempearth and the leader in HEMP and Marijuana developed the world’s first HEMP plane. Founded and Incorporated in 2014, Hempearth produces and offers a variety of products. Florida company, Velocity, Inc. is set to manufacture the plane and a signed manufacturing contract is in place. Hempearth Group is also just finishing up some never been developed HEMP composites now in Australia post pandemic that is set to replace all fiberglass in aviation and many other industries.

Hempearth Founder Derek Kesek is interested in hemp as a sustainable material. “This is the kind of future we all want here on Earth,” Kesek says, hinting at hemp’s potential as a building material. Hempearth is producing 3 different patentable materials for aviation.

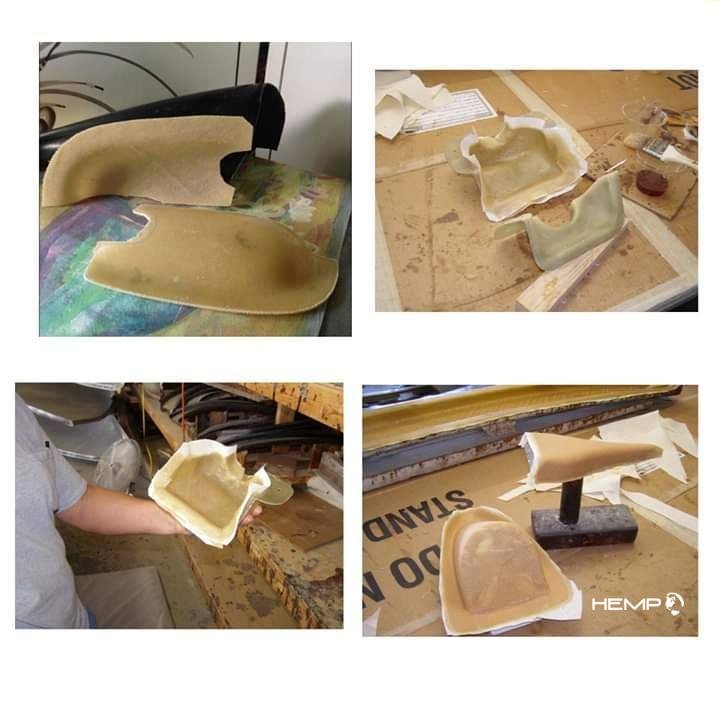

Weave #1 (Patent Pending) is the most important and is what all the small molded parts shall be made of in the worlds 1st Hemp Plane. The weave allows stretching or collapse regardless of how the mold is designed.

Weave #2 (Patent Pending) is a fine directional cloth and shall be used as the outer layer of many of the planes lay-ups because it takes less filler to provide the fine surface required for painting.

Weave #3 (Patent Pending) is a heavy cloth that shall be used for several parts where they do not need to conform to a curved surface but where the surface is relatively flat. A firewall is an example of a flat surface where this particular weave/cloth shall be used. This weave/cloth shall also be used in the making of the Hemp Planes wings where compound curves are not present.

These materials are unlike anything every produced on earth, invest now in Hempearth and take advantage of this amazing opportunity before its too late.