Today, 95% of the modern surfboards are made out of petrochemical materials, the same toxic materials that were widely introduced in the industry in the late 1950’s. So entering the second decade of the 21st century we believe it’s about time to take radical steps and change our boards for something new , something more sustainable with better quality.

3 reasons why your next surfboard should be an sustainable surf.

1. Become sustainable

The components of a surfboard travel around 10 000 km before we can ride it And a 3-kilogram-surfboard produces 6 kilograms of toxic and non-recyclable waste.

According to a Sustainable Surf survey , more than 80% of surfers are concerned with ocean’s health, more than 80% of them already consider having a strong tendency to behave in an environmentally friendly way.

Paradoxically, surfing boards produced with that kind of background is quite far from living in accordance with our goals of sustainability.

2. Better quality, new technology

Using a new way of building surfboard you also choose a board with more quality. Several features make these boards unique.

Thanks to an innovative “New” vacuum process, significantly less resin is required to saturate the layers of fibre more thoroughly than was possible with conventional methods. The vacuum process guarantees that the resin is uniformly distributed and completely fills the holes between the fibres. This creates twofold advantages for the final product: the finished composite material is particularly light and yet still demonstrates great stability.

3. Be part of the change, influence other surfers

One can’t change the entire world but one can influence others to change the way we think of our surfboards. Once you start riding an HEMPEARTH surfboard and start talking about the benefits, giving others your feedback on it you will definitely inspire others to act the same way and step by step we can become a more sustainable surfing community thanks to you and your influence too.

The Perfect Ingredients : Epoxy , Hemp and Recycle Foam

Epoxy

- Epoxy resin is up to 33 percent stronger than the standard resin used in polyurethane-fiberglass surfboards;

- An epoxy surfboard has more air in its core, so it floats better than a PU-based board;

- An EPS board is easier to paddle and will enter a wave faster than a standard fiberglass surfboard;

- The EPS/epoxy formula allows shapers to create boards with thinner rails while maintaining above-average flotation;

- A polystyrene foam-based surfboard is lighter than a traditional polyurethane foam-based surfboard;

- It’s the perfect surfboard for beginner surfers;

- It’s an excellent choice for taller and heavier surfers;

- It’s a good option for mushy waves;

- It’s the ideal surfboard for older surfers or surfers who are out of shape and still getting back to the waves after a long period off;

- When it comes to waterlogging, the epoxy surfboard’s outer shell is more resistant to cracks and fissures. It is not indestructible, but it is pliable, tough, and handles dings better;

- It doesn’t deform in the foot placement area like a PU board because the deck is dense and strong;

- An epoxy surfboard is easier to get through flat sections;

- In longboard models, it often feels cruisey;

- An epoxy surfboard is very durable compared to traditional fiberglass/polyester and is safer to travel with on a plane;

- Building an EPS surfboard uses fewer chemicals and is more environmentally friendly than a standard polyurethane board;

- An EPS blank can be combined with flax cloth and bio-resin;

- EPS can be recycled;

- An EPS board is great for aerial surfing.

Recycling Foam

This innovative technology allows all types of EPS (foam) regrind, not just surfboard scraps, to be made into a high grade, mouldable material and be put back into production again.

Collected post-use EPS is put into a mulching machine that breaks down the material to smaller pieces called “re-grind”. Loose re-grind pieces are conveyed into a holding bag and fed down into a machine that compresses the regrind into highly dense rectangular blocks (20pcf). The blocks of recycled EPS are then reprocessed into Envirofoam that is remanufactured into blanks on the same equipment that makes the Virgin EPS blanks. Envirofoam material can be recycled and reprocessed into a usable blank material over and over… and over… and over… again.

Hemp

People have used Hemp for hundreds of years. They’ve used the super-strong fiber for ropes, clothing, building materials, and more. History acknowledges that the fibers are some of the strongest in nature. While it might just be a new industry to some, hemp has been used for industrial and commercial uses for ages.

Hemp has eight times the tensile strength compared to cotton and is way more durable. Plus, the fact that hemp is natural and easy to grow makes it the ideal element for making surfboards.

Thanks to the strength of this material, they can be confident that the boards will last. Using a board that is eco-friendly helps the environment. It also works to decrease the demand for non-renewable resources in our environment.

The ideas of using hemp-based surfboards and paddleboards are ones that carry multiple benefits for the environment as well as the surfers themselves.

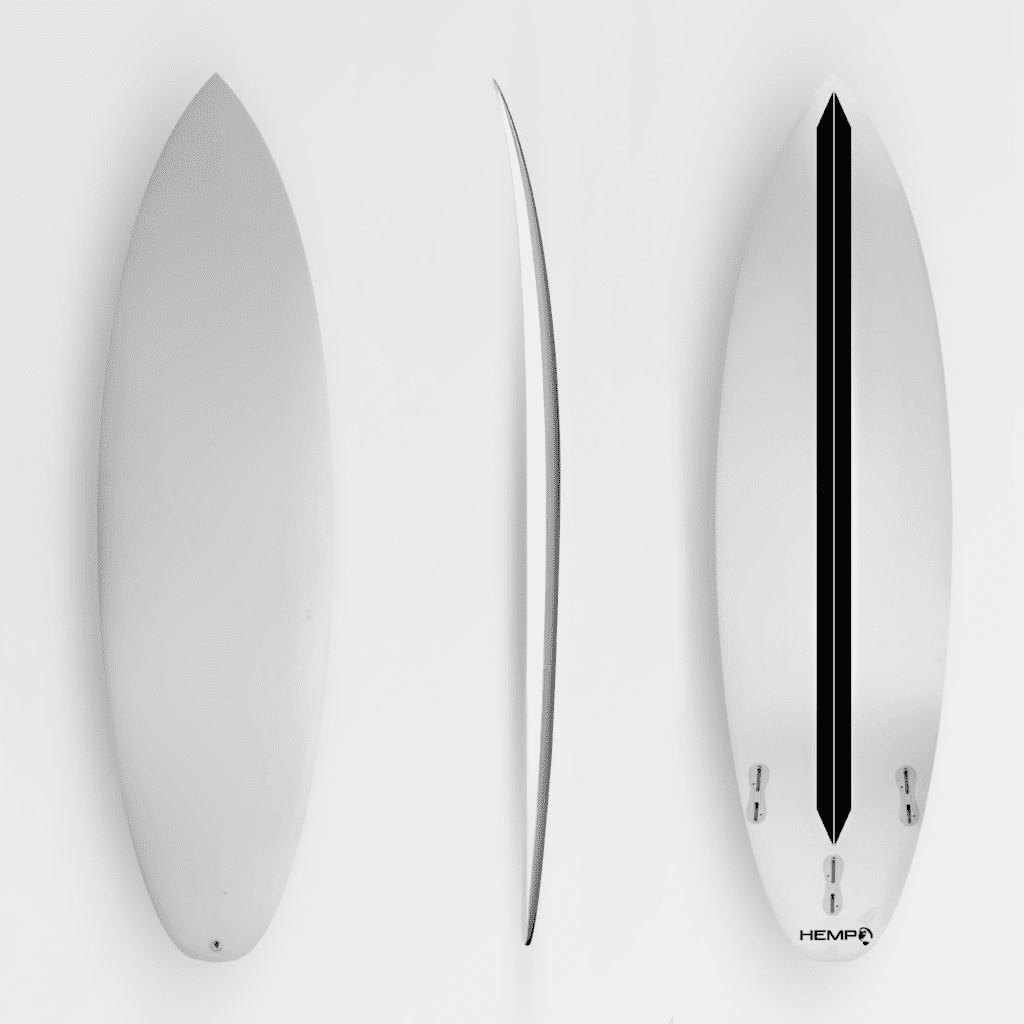

Hempearth High Performarce Surfboards

The World’s Most High Tech, High Quality, Revolutionary, Innovative Sustainable Board On The Planet. Adding 100% hemp fiber cloth to a performance surfboard design, truly unites speed and agility with improved durability.

Our surfboards represent American craftmanship, sustainable values, visionary shaping, and surfing expertise to offer a high performance hemp surfboard.

- 100% HEMP Fiber

- 100% Fiberglas Free

- Vacuum Technology

- FCS Boxes – Available in 3, 4 and 5 Fin Systems

- Ultra Light But Super Strong

- HEMP Basalt Drive

- Eco Epoxy

- No Wood Stringer

- Recycled Foam

Final Thoughts

Surfing is an exhilarating sport that allows us to connect with nature and the ocean. However, what many of us don’t realize is the significant impact that surfing can have on the environment.

The environmental impact of surfing comes from various sources, including the materials used to make surfboards, the waste generated during the production process, and the way we dispose of our boards when they are no longer usable.

HEMPEARTH Surfboards are are unlike anything on the market, most board companies do not Vacuum bag for Quality and assurance.

Hempearth has taken surfboard building to the next level with super sustainability at the forefront.