From the plane your fly in, to the Car you drive, and to the Computer And Phone you use, HEMPEARTH is taking all industry by storm with is 100% Hemp Aircraft Composites a World’s first.

HEMP FIBERS

HEMP fibers are enjoying increased use because of their very low weight, excellent insulation properties, and their “green” attributes:

*Sustainability

*Expending up to 90% less energy in their production vs synthetic fibers

*Energy efficiency

*Biodegradable when disposed of and renewable via farming

*When incinerated, natural fibers give off no more carbon dioxide than was originally consumed during lifetime of the fibers

*Carbon dioxide neutrality

Hemp fibers are considered as one of the strong member of bast natural fibers family, which are derived from the hemp plant. Nowadays, these fibers have received wide acceptance as reinforcements in composite materials on account of their biodegradability and low density compared with artificial fibers. Also these materials have inherent mechanical, thermal, and acoustic properties . Surface functionalization of hemp fibers is of relevant importance to widen its applications.

Hemp fibers are increasingly being used in composite structures. They are caracterized by:

*A density of 1.4 gr/cm3

*A similar specific tensile strength compared to E-Glass

*A slightly superior specific modulus rating compared to E-Glass

*Uses more appropriate for monolithic structures versus sandwich structures

*Dampening properties that make it ideal for acoustic and vibration/shock absorption applications such as transportation.

*As a renewable resource, Hemp fibers are considered a “eco-friendly” material.

COMPOSITES

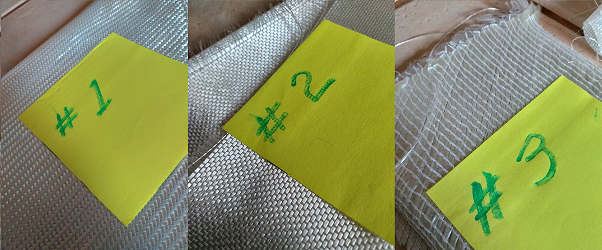

HEMP Thread comes on a bobbin , it has a certain amount of thread per each bobbin, to give you an example our first sample runs are set to use 500 kg of fiber thread, which shall do 3 different style composite weaves, as follows #1 – is the most important and is what all small molded aircraft parts of made of, the weave allows stretching or collapse regardless of how the mold is designed, #2 is a fine single direction cloth and is used as the outer layer in many lay-ups because it takes less filler to provide the fine surface that is required for painting, #3 is a heavy cloth that is used for several parts where they do not need to conform to a curved surface but where the surface is relativaly flat, a fire wall is an an example of a flat surface where this particular cloth shall be used, this weave shall also be used with aircraft wing construction where compound curves are not present.

USES OF HEMPEARTH COMPOSITES

*Transportation and Automotive

*Electronics

*Civil Engineering

*Aeronautics

*Sports and Leisure

*Energy, Oil and Gas

*Tooling

Hemp fiber has been found to be very cost-effective, with high strength and can be used as an excellent reinforcement fiber for replacing glass fiber, at a much lower price. The increasing commercial availability of hemp fiber and the demand for low cost, high strength fibers has resulted in new applications for hemp, particularly in automotive and construction products.

Aside from its high strength, hemp has been recognized for its elasticity, ease of processing and recycling. Also, hemp fiber’s staple length and strength can be modified according to the needs of the consumer.

Investment

HEMPEARTH has been in business since 2014 with 1000’s clients globally.

Incorporated in 2014, we have already been Featured In HIGH TIMES Magazine, CNN, Pilot Magazine, USA TODAY, THE TORONTO STAR and publications worldwide. HEMPEARTH Group has quickly become leader in HEMP and Marijuana.

“We actually have physical products and have a viable road map.” — Derek Kesek, Hempearth Founder

Generating New ECO Bio Products

100% HEMP FIBER SURF BOARDS, & SUP BOARDS, HEMP Composites For Aircraft and more, 100% Hemp Board, Hemp Plastic

Hempearth Group Ltd. has produced The World’s First 100% HEMP Fiber SUP Paddleboards, along with their own line of 100% Hemp Fiber Surf Boards that are 100% fiberglass free using an Eco-Epoxy Resin made from Eco Resin and Recycled Foam. Sustainable Hemp Aviation Composites have also been developed in collaboration with companies out of Montreal, QC and Australia. These innovative and revolutionary new products are unlike anything ever produced on the planet, but most of all their sustainable. One of the best investment opportunities out there right now.